Recent Post

Magnets in Restaurant Kitchens

Global supply challenges and HYAB’s role

Electromagnets – a more controllable magnet

Magnetic filtration in the process industry

Sheet metal handling – Easier with magnets

Magnet manufacturing process: From raw material to finished magnet

Published: 2025-01-27 09:47:47 • Daniel Gårdefelt

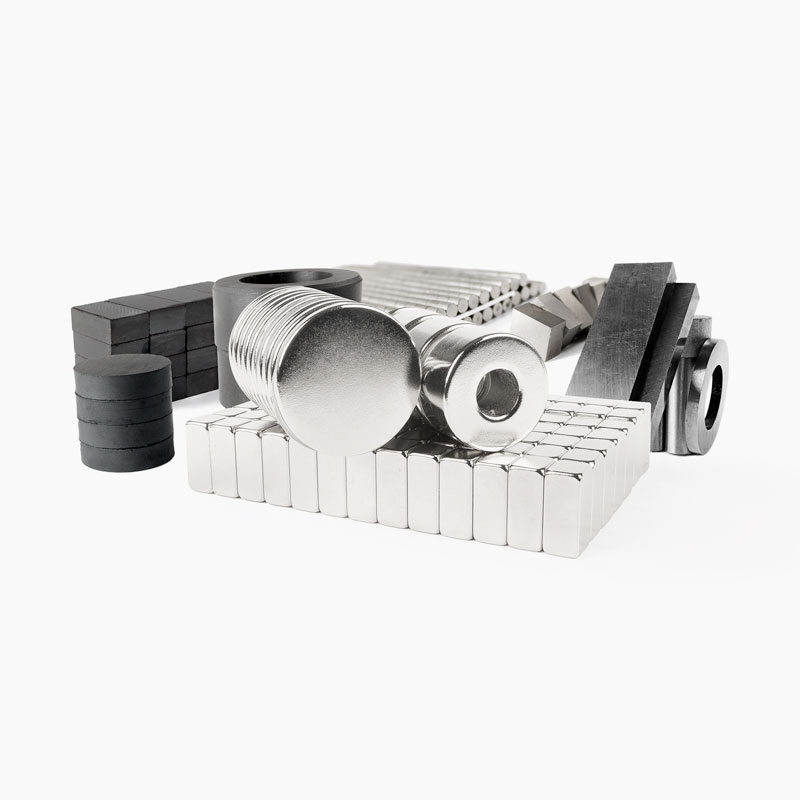

In today's technology, magnets are in everything from refrigerator magnets/advertising magnets to speakers and sophisticated medical devices. But how are these powerful metals made? Today we explain how magnets are made step by step.

Here at Hyab we help you with the entire process. From idea, construction and design to finished product. We offer you as a customer a smooth and optimal overall solution, whether it is a single permanent magnet or an entire magnet system.

Step 1: Choosing materials

The choice of suitable material is the first step in the manufacture of magnets. Magnets are made of the following materials:

1. Ferrite: Cheap and common in household items where no maximum strength is a necessity.

2. Neodymium, or NdFeB: Most powerful magnets that are used in advanced products where strength is high focus.

3. Samarium Cobalt, or SmCo: Have good corrosion resistance and high magnetic strength, making them ideal for demanding industrial applications.

4. Alnico: An alloy of aluminum, nickel and cobalt. High temperature stability and are cost-effective, but they have lower magnetic strength.

Alnico magnets are not sintered and are manufactured in a slightly different way than described below. In the manufacturing process, the raw materials (aluminium, nickel, cobalt and sometimes iron, copper and titanium) are melted and poured into molds to create the desired shapes. After hardening, they undergo heat treatment and magnetization to develop their magnetic properties.

Read more about the differences between the different magnet materials on our dedicated permanent magnet page.

Step 2: Production of powder

"Powder manufacturing" is a process used for strong magnets such as neodymium magnets. This process involves:

1. Mixing of materials: Mix the raw materials into a fine powder

2. Cooling and melting: At high temperatures, the powder is melted and then quickly cooled to form small, even grains.

Step 3: Pressing

The powder is then pressed to the desired shape under high pressure. For neodymium magnets this is often done in a magnetic form to ensure that the magnetic domains are correctly directed. Pressing can be done at room temperature (cold pressing) or at high temperatures (varmpressning).

Step 4: Sintring

After pressing, the material is heated in a process called sintering. The small particles bind together during sintering, creating a solid and dense structure. The temperature during sintering is usually very high, often above 1000°C, depending on the material.

Step 5: Machining

After sintering, the magnets are processed to precise dimensions by cutting, grinding and other processing methods. This step is crucial to ensuring that the magnets have the dimension with the correct tolerance so that it will fit perfectly where they are to be used by the endcustomer.

Step 6: Magnetization

After the processing, it is time to magnetize the magnets. Exposing them to a strong magnetic field allows the magnetic domains of the material to be directed in a certain direction. The magnetization process varies depending on the type and purpose of the magnet.

Step 7: Surface treatment and coating

When it comes to neodymium and samarium cobalt magnets, a coating is usually applied to the magnets to protect them from corrosion and other damage. The most common coating for neodymium magnets is first a layer of Nickel followed by a layer of Copper followed up by a last layer Nickel. Another common coating is Zinc or Epoxy. Read more about all coatings on our information page on Neodymium Magnet Surface Treatments.

Ferrite magnets are not surface treated because they are already very resistant to corrosion. They consist mainly of iron oxide and other metal oxides. The chemical composition of the ferrite material causes it to naturally form a passive oxide film on the surface, protecting it from further corrosion.

Step 8: Quality Assurance

Before packing and delivering, the magnets undergo extensive quality controls. Testing their magnetic strength, dimensions and resistance to various environmental factors is part of this process.

Finally

The manufacturing of magnets is a complex process that combines advanced material science and precision machining. Every step is required to ensure that the magnets meet the high demands of today's technology, from the choice of raw materials to the final quality control. The next time you use a magnet, think about the exciting path it has taken from the base to the final product.

Next step? Contact us to discuss how we can help your company with customized magnetic systems!