Magnet Facts

What is magnetism?

People have known, explored and used magnets for thousands of years. Still we have problems explaining what it really is, there seems to be something magical about the phenomenon.

Sure you can get amazed about how moving pictures can be transmitted to TV receivers over the hole world, but it's still a technique that is created by man. Even for science magnetism is something that is taken for granted, rather than created, and hard to explain. In general its hard to reduce magnetism, i.e explain it in more basic terms, and this is reflected in scientific terminology.

Visual light is composed by electro magnetic waves, the same type of waves if used on other frequencies can heat food in our microwave ovens, give us a summer tan or transmit sound and pictures to our TV- receivers. Together with gravitation, electro magnetism is also generally counted as one of the four basic forces in nature. In some scientific and philosophic views, at least figuratively, it is even considered to be the cause of life it self. You can believe what you want about that but it's still gives an indication about how hard it is to explain and how "magical" magnetism is. Luckily we don't have to go so deep into describing magnetism in order to use it.

An magnetic field is created around every electrical flow. In that way even a cord to a lamp becomes an electromagnet. The magnetism around an ordinary lamp cord is insignificant, but if you twine the cord around coiled spools, the field is increased. This technique can give very powerful electromagnets, with a power that can be turned on and off. Just like the permanent magnets, the electromagnet has a traction force on some materials. Object of such a materials, those that we in common language call "magnetic", also have the potential to work as magnets them self.

An ordinary screw driver can, after being in contact with a magnet, be used to pick up lighter screws. But these magnetic characteristics are at this point week and this effect also decrease relatively quickly. The materials in permanent magnets have to be able to be charged to a higher magnetic electric level and be resistant against demagnetization, with other words they have to be able to obtain their magnetic characteristics in different environments. With the new materials and production methods we have nowadays we can manufacture magnets that by far exceed the classic magnets.

What different types of magnetic materials is available today?

| Strength | Lowest price | Moisture resistance | Max temp | |

|---|---|---|---|---|

| 1 | Neodymium | Ferrite | Ferrite | Alnico |

| 2 | Samarium Cobalt | Neodymium | Alnico | Samarium Cobalt |

| 3 | Alnico | Alnico | Samarium Cobalt | Ferrite |

| 4 | Ferrite | Samarium Cobalt | Neodymium | Neodymium |

1.PERMANENT MAGNETS

Neodymium

Sintered neodymium-iron-boron (NdFeB) also known as "Supermagnets" is today the strongest material on the market. Hyab stocks neodymium-magnets in thousands of different dimensions and geometries. We also produce magnets with the customers own specification requirements. If you do not find what you are looking for, do not hesitate to contact us!

The strength of the neodymium material is adjustable during manufacture. Hyabs standard is N36 (energy product (BH)max [MGOe]: 35 - 37), but it is possible to get up to N52 (energy product (BH)max [MGOe]: 50 - 53). N52 is approx 40 - 50% stronger than N36. See our material grade list for all values for each individual neodymium grade along with maximum working temperature.

By default, the neodymium magnets can withstand 80°C, but we stock several variants that can withstand 120°C (H), 150°C (SH), 180°C (UH), 200°C (EH), 230°C (AH). Exceeding the maximum working temperature, the magnet will begin to demagnetize.

| Contents in NdFeB | Contents in % |

|---|---|

| Neodymium [Nd] | 35% |

| Iron [Fe] | 61% |

| Boron [B] | 1.2% |

| Dysprosium [Dy] | 0.8% |

| Copper [Cu] | 0.2% |

| Aluminium [Al] | 0.9% |

| Gallium [Ga] | 0.9% |

NdFeB-magnets oxidate easily, therefore the magnets are always delivered with a galvanic coating. Our standard range is coated with nickel or zinc. What distinguises Zn (Zinc) and NiCuNi (Nickel-Copper-Nickel) from eachother is that Zn can have a slighty better adhesion when it comes to gluing and taping. If the magnet is to be in a humid environment, we recommend a nickel-epoxy treatment.

See our coating page to decide which surface treatment is best for your application!

Nickel (Ni-Cu-Ni)

Zinc (Zn)

Epoxy

Gold (Au)

Rilsan

Rubber coated

Alnico

Aluminum-nickel-cobalt was developed in the 1930s. Alnico is a very temperature resistant material that is heat resistant up to 500°C. The material has also a high remanence, Br. This have made Alnico a popular solution in, among other things, sensitive measuring instruments. Alnico is stronger than Ferrite, but weaker than both Samarium cobalt and Neodymium.

Alnico has a high magnetic strength and a low resistance to being demagnetized and re-magnetized. If coils of wire are wrapped around a alnico magnet, it can easily magnetize and demagnetize by electricity flowing through the coils. This makes it easy to regulate the strength of an alnicomagnet, which is not as easy in the other magnetic materials.

| Contents in AlNiCo | Contents in % |

|---|---|

| Aluminium [Al] | 8% |

| Nickel [Ni] | 14% |

| Cobalt [Co] | 24% |

| Iron [Fe] | 54% |

Ferrite

Sintered strontium ferrite is a popular magnetmaterial, much due to the low price. It is also the material with lowest strength. Ferrite magnets are used mostly in speakers and motor segments. The ferritematerial has a max working temp. of 250 °C.

Just like with the other magnetic materials, you can increase the energy content in ferrite and get a stronger magnet. By default we use a grade called Y30H-1 (previously called FXD380), there are also many in the slightly stronger grade Y30H-2 (previously called FXD400).

We accept inquiries in all different sizes and geometries, so do not hesitate to contact us if you do not find what you are looking for.

| Contents in Ferrite | Contents in % |

|---|---|

| Iron3oxide [Fe2O3] | 90.1% |

| Strontium [SrO] | 9.9% |

Samarium Cobalt

SmCo is the high-energy material that can withstand the highest temperature, above 350 ° C, and has been used for several decades for engine segments and other high-temperature applications. The development from SmCo5 to Sm2Co17 has meant further improvements in terms of magnetic properties. Hyab provides a number of qualities.

Like neodymium magnets, samarium cobalt provides a lot of magnetic strength (but not as much as neodymium magnets) compared to their size, and because they are rare earth magnets, they have extremely high resistance to demagnetization from external magnetic fields. This is what makes samarium cobalt suitable for applications for the marine, automotive, aerospace, military and manufacturing industries.

Although Samarium cobalt magnets are not as strong as neodymium magnets, they have two distinct advantages over the stronger material. They have a higher maximum working temperature and are much more resistant to corrosion because the SmCo magnet barely contains any iron. They can also withstand an enormous cold - below the absolute zero point (-273.15 ° C) to be more specific.

If you do not find the dimension or geometry you are looking for, do not hesitate to contact us as we produce magnets according to customer specifications.

| Contents in SmCo | Contents in % |

|---|---|

| Samarium [Sm] | 25% |

| Cobalt [Co] | 52% |

| Copper [Cu] | 4% |

| Iron [Fe] | 14.6% |

| Zirconium [Zr] | 4.4% |

2.PLASTIC BOUND

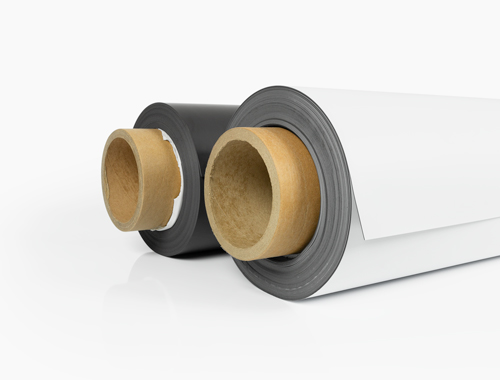

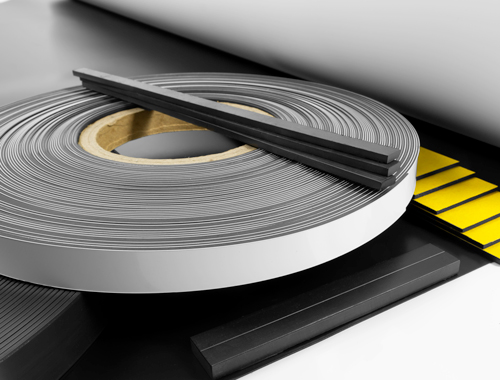

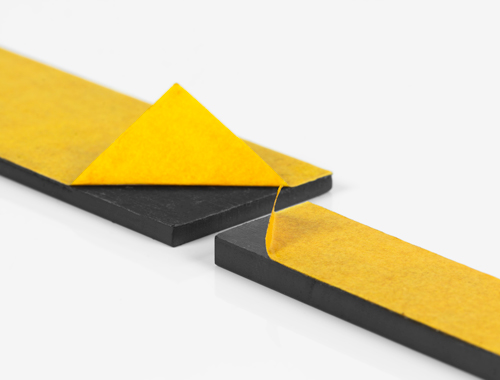

Plastic Bound ferrite is a soft and flexible material that can be punched or cut to a desired shape. The material adapts well to curved surfaces and is therefore ideal for signs, decals for cars etc.

We separate our products anisotropic and semi-anisotropic materials, where the latter have only one magnetic side. Tapes are usually semi-anisotropic, while sheets and strips are available in two versions.

See our plastic bound category for magnetic sheet, magnetic strip either on roll or cut pieces. We also have a wide sortiment on different products for inventory labeling.

3.MAGNET SYSTEMS

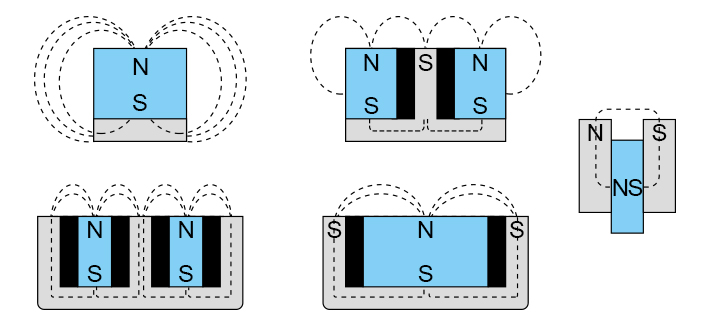

Choosing the right magnet system is often critical to the finished product. If for example the function of the magnet is to fix or lift, a neodymium magnet inside a iron housing can be many times stronger than a simple magnet. By implomenting steel and iron in magnet assemblys, we can affect the magnetic field by how we want the end product to work. Is the job to separate steel sheets? Then longer magnetic fields is necessary.

Here you can see more examples on how iron affects the strength on magnetic systems, compared to the magnet alone.

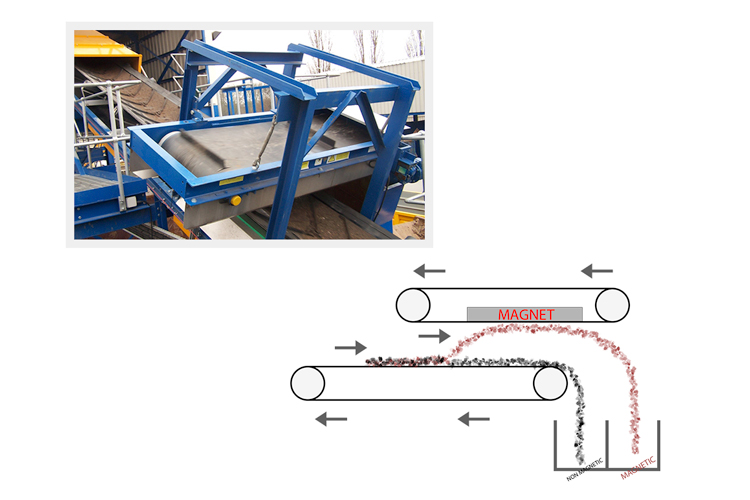

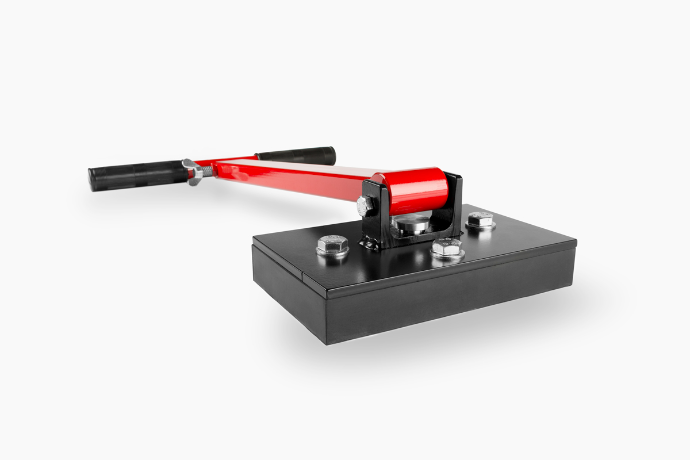

Steel sheet separators and Magnetic filter bars

One of the tasks of the steel sheet separator is to separate plates, so that you can easily avoid tangles and easily access plates, regardless of whether they are oily, sticky, large or small. The separator ensures a smooth production process by making sure you pick up one sheet at a time. Do you need extra strength or are the plates so large that they sag? Then use a system where you insert several separator magnets into one assembly. We specify the thickness of the plates recommended for the plate separator in each individual article.

Note that these magnetic systems (both sheet metal separators and overband magnets) have long magnetic fields and are extremely strong. Unsafe handling can cause fingers or skin to get caught between the magnets. This can lead to bruising, contusion or, in the worst case, bone fractures. Magnets can also affect the function of pacemakers and implanted cardiac defibrillators. Read more about this under Magnet facts.

The separators can also be used as a conveyorseparator and the use of separation of metals in sewage and in chemical lab etc. We often adapt these "separators" for machines with built in de-magnetizing and have many products cad -made that is not showing on our website.

Hyab has made huge conveyorseparators for de-mining and locating metals in concrete foundations, etc.

See our steel sheet separators and overband magnets / conveyorseparators here

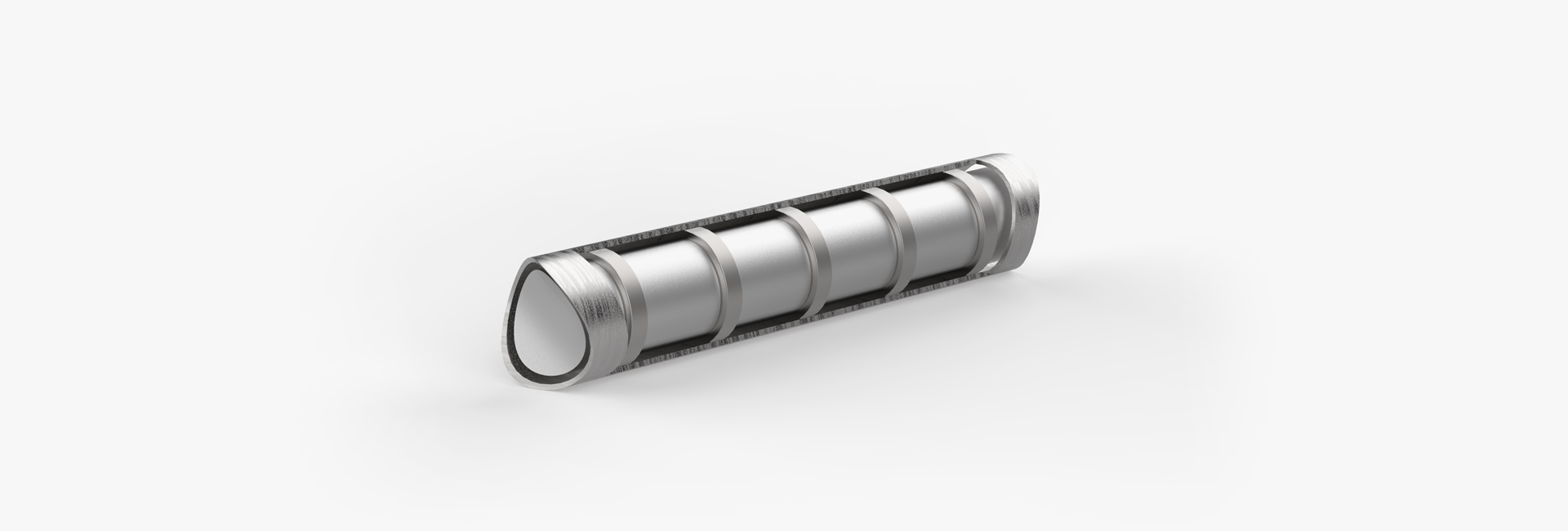

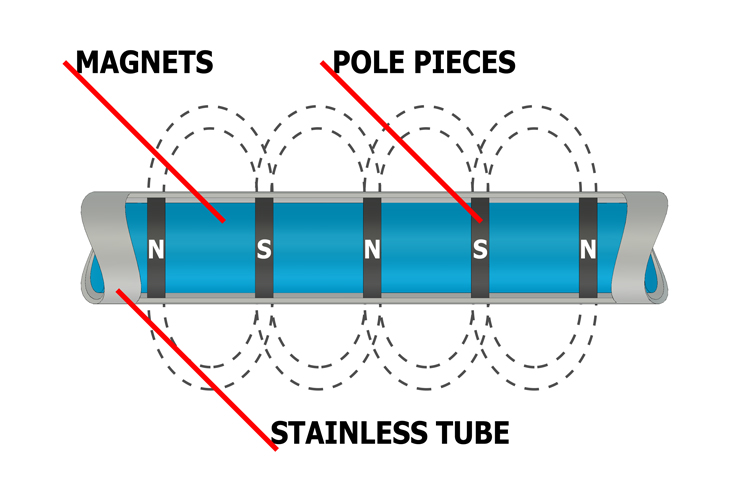

Magnetic filter bars for filtering magnetic chips and fine iron-containing particles/dust. The rods are very corrosion resistant, are fast and easy to clean and is therefore a good choice when handling food/groceries.

Our neodymium rods are available in 6000, 8000 or 10000 Gauss. By default, we specify them for 10000 Gauss. They can be used up to temperatures of 80°C. However, it is possible to increase the maximum temperature by using more heat-resistant magnets. Contact us to customize your separator bar, or why not a complete filter system.

Also available in ferrite materials, then a typical fluid density of 1500 Gauss, and can be used up to 150°C.

A typical application is separators mounted as a grid for filtration, like image above.

You can find our filter bars hereMAGLIFT - Manhole opener

MAGLIFT is a tool designed for ergonomically handling and lifting manhole covers and plugs aswell as *any surface. Whether you need a small practical tool for small to standard 600mm lids to larger Square lids with hinges, we have what you need. We manufacture a lineup of different models for different situations.

Awarded with numerous recognitions and certifications, the manhole cover lift MAGLIFT is proven in the professional world as a necessary part of handling equipment.

Combining working time and respect for health, MAGLIFT is used by many companies of construction, plumbing and telecom. Trust MAGLIFT to preserve your body and your mind!

Magnetic catches

A magnetic catch is a latching mechanism that uses a magnetic force to hold two objects together. Most magnetic catches consist of an ironplate and a magnet. The magnet is installed on one object, whereas the armature plate is installed on the other object. After installing both components, a magnetic force will hold the two objects together. You can then separate the joined objects by pulling them away from each other, thus breaking the magnetic force.

While there are other hardware solutions available to hold objects together, magnetic catches offer several benefits. For starters, they are easy to install. You just have to install the magnet on one object and the armature plate on the other object. Most magnetic catches feature holes for screws. You can drive screws into the magnet and armature plate to install them on the appropriate objects.

Magnetic catches are long-lasting. Magnetics can and do lose their magnetism — but this isn’t something that happens overnight. It can take many years or even decades for a magnet to lose its magnetism. As a result, magnetic catches are long-lasting

See our magnetic catch category for all of our different models. If you can't find what you are looking for, dont hesitate to call. We can help you finding the best magnetic solution of your problem!

4.ELECTROMAGNETS

Hyab stocks a large variety of electrical magnets such as lifting magnets, holding magnets and pull / push magnets. Holding magnets are used for lifting or fixating details. Dragmagnets or solenoids perform a stroke and can replace pneumatics in many designs. The magnets are either single acting, which means magnets pulling / pressing in one direction while the return takes place in other ways (eg with spring), or they are double acting with two coils and reversible kind. Hyab's stardard is 24VDC and 100% ED.

Extreme electromagnets

Extreme electromagnets starts on a diameter of 200mm and a lifting force of 560kg and up to a diameter of 600mm with a lifting capacity of more than 5 tons!

Designed for short distance handling ferrous resides such as raw steel, scrap, cast iron, ferrous chips etc. Thanks to their dependedability and swiftness they are ideal for fixed and mobile lifting, such as: bridge and tower cranes, monorails, automatic loading system for machines and assembly lines. In Hyabs standard range of electromagnets you find extreme electromagnets, electrical holding magnets and pull and push magnets.

Solenoids / drag & holding -magnets

Solenoids, or pull/push magnets can replace pneumatics in many constructions The magnets are either single-acting, that is magnets pulling / pressing in one direction while the return happens in another way (eg, spring), or double-acting with two coils and reversible nature. HYABs default is 24 VDC, 100% ED

Permanent electromagnets

These permanent solenoids are electrically powered on / off systems. They consist of a permanent magnet and a DC excited coil to neutralize the permanent magnetic field at the poles.

These systems are used in a powerless state where a load, a workpiece or machine parts must be held reliably and safely. The housing is completely zinc plated and the coil is vacuum-stoppered.

The difference between a regular cylindrical electromagnet and a permanent electromagnet is that a permanent electromagnet always is ON (magnetic) when you don't give it power. And OFF (non-magnetic) when you give it electricity. Our Electro permanent magnets has a low ED, this means that they cannot be connected for very long. The usual time for a Connection is approx 8 seconds per minute! (ED's is a percentage measure of the connection time. If the magnet are supposed to work shorter (lower ED), you can increase voltage and get more power)

How magnets affect pacemaker's.

The implantable pacemaker is a Swedish invention and makes the heart beat at the right pace. The pacemaker's job is to send electrical impulses to the heart so that it beats regularly.

NOTE: before you read

We are not a doctors, so we can only recommend the safety of your pacemaker. For better guidance, consult a certified physician or pacemaker manufacturer. We take no responsibility for how our customers use their magnets against medical equipment.

With that said, we can still get numbers on what distance and how many gauss a standard, modern pacemaker can be appointed for.

How many Gauss / Tesla can a pacemaker be exposed to

Many sources [1], [2], [3] mention the numbers 5 - 10 Gauss (0.5 - 1.0 milliTesla = mT) as the maximum magnetic field where a pacemaker should work properly. These are typical values that pacemakers are expected to hold.

[1] - "Since 2003, all European manufacturers have been required by European standard EN 45502-2-1 to design pacemakers in such a way that static magnetic fields up to 10 Gauss (1.0 mT) do not affect safety and functionality."

[2] - "The EU Working Directive defines the pacemaker limit in static magnetic fields at 5 Gauss (0.5 mT).

[2] - "The EU Working Directive defines the pacemaker limit in static magnetic fields at 5 Gauss (0.5 mT).

A 2015 study of the EU Labor Directive by the Federal Ministry of Labor and Social Affairs concludes that the safety and functionality of pacemakers in static magnetic fields is also guaranteed with a magnetic field strength of up to 7 Gauss (0.7 mT)."

[3] - "A report on pacemakers and music players from Boston Scientific, one of the largest manufacturers of pacemakers, states - described in the Pacemaker and Defibrillator Operating Instructions, exposure to strong magnetic fields,> 10 Gauss (1 mT), can alter implanted device function."

As this applies to medical equipment, we suggest sticking to the lowest, most conservative value of 5 Gauss (0.5 mTesla).

How many Gauss / Tesla can a pacemaker be exposed to

This depends on the size and magnetic material of the magnet. But to estimate a value, you can use our magnetic calculator. Enter your desired dimensions on the magnet and adjust the Distance to change the Bz (Gauss) value - or simply put; the magnetic flux density at the distance from the magnet.

DISCLAIMER; The values you get from our magnetic calculator are only theoretical. These can vary from the numbers you get in reality. We take no responsibility for how our customers use their magnets against medical equipment.

Here is a table with some examples of what distance you need from the magnet to get below 5 Gauss, in different sizes Neodymium cylinder magnets. Taken from our magnetic calculator.

| NEODYMIUM N35 distance [mm] | Diameter in [mm] | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thinkness in [mm] | Ø 1 | Ø 2 | Ø 3 | Ø 4 | Ø 5 | Ø 6 | Ø 7 | Ø 8 | Ø 9 | Ø 10 | Ø 20 | ||

| T 1 | 6.3 | 10.2 | 13.4 | 16.4 | 19 | 21.5 | 23.9 | 26.1 | 28.3 | 30.3 | 48 | ||

| T 2 | 7.6 | 12.5 | 16.6 | 20.3 | 23.7 | 26.8 | 29.8 | 32.7 | 35.4 | 38 | 60.7 | ||

| T 3 | 8.4 | 14 | 18.7 | 22.9 | 26.8 | 30.5 | 34 | 37.2 | 40.3 | 43.4 | 69.4 | ||

| T 4 | 9 | 15.2 | 20.4 | 25 | 29.3 | 33.3 | 37 | 40.7 | 44 | 47.4 | 76 | ||

| T 5 | 9.4 | 16 | 21.7 | 26.7 | 31.2 | 35.6 | 39.6 | 43.5 | 47.4 | 50.8 | 81.8 | ||

| T 6 | 9.7 | 16.8 | 22.7 | 28 | 33 | 37.4 | 41.8 | 46 | 50 | 53.8 | 86.5 | ||

| T 7 | 10 | 17.4 | 23.8 | 29.2 | 34.4 | 39.2 | 43.6 | 48 | 52.2 | 56.4 | 91 | ||

| T 8 | 10.2 | 17.9 | 24.4 | 30.2 | 35.6 | 40.6 | 45.4 | 50 | 54.3 | 58.5 | 95 | ||

| T 9 | 10.4 | 18.3 | 25 | 31.2 | 36.8 | 42 | 47 | 51.6 | 56 | 60.5 | 98.2 | ||

| T 10 | 10.6 | 18.7 | 25.7 | 32 | 37.8 | 43.2 | 48.2 | 53.2 | 57.8 | 62.3 | 101.5 | ||

| T 20 | X | X | X | 37.5 | 44.6 | 51.4 | 57.8 | 64 | 70 | 75.6 | 125 | ||