We develop, design and build magnetsystem with the highest technical skills. We have one of the widest range of magnets in Europe and help customers with custom solutions every day. We have inhouse production where we assemble magnet systems for all possible constructions. If you have an upcoming or ongoing project and need assistance about magnets, do not hesitate to contact us. Since we have such a wide range of magnets on stock, we can almost always provide our customers with an instant solution with shipping same or next day.

See Our Company page for more information about Hyab.

POPULAR PRODUCTS

Do you perfer browsing for articles in a catalog? Check out our latest version! If you can't find what you are looking for, don't worry. Contact us and we will make it for you!

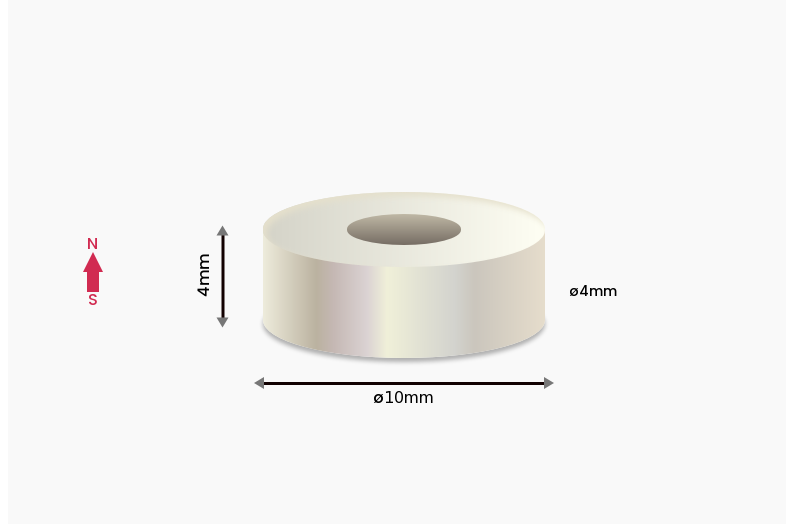

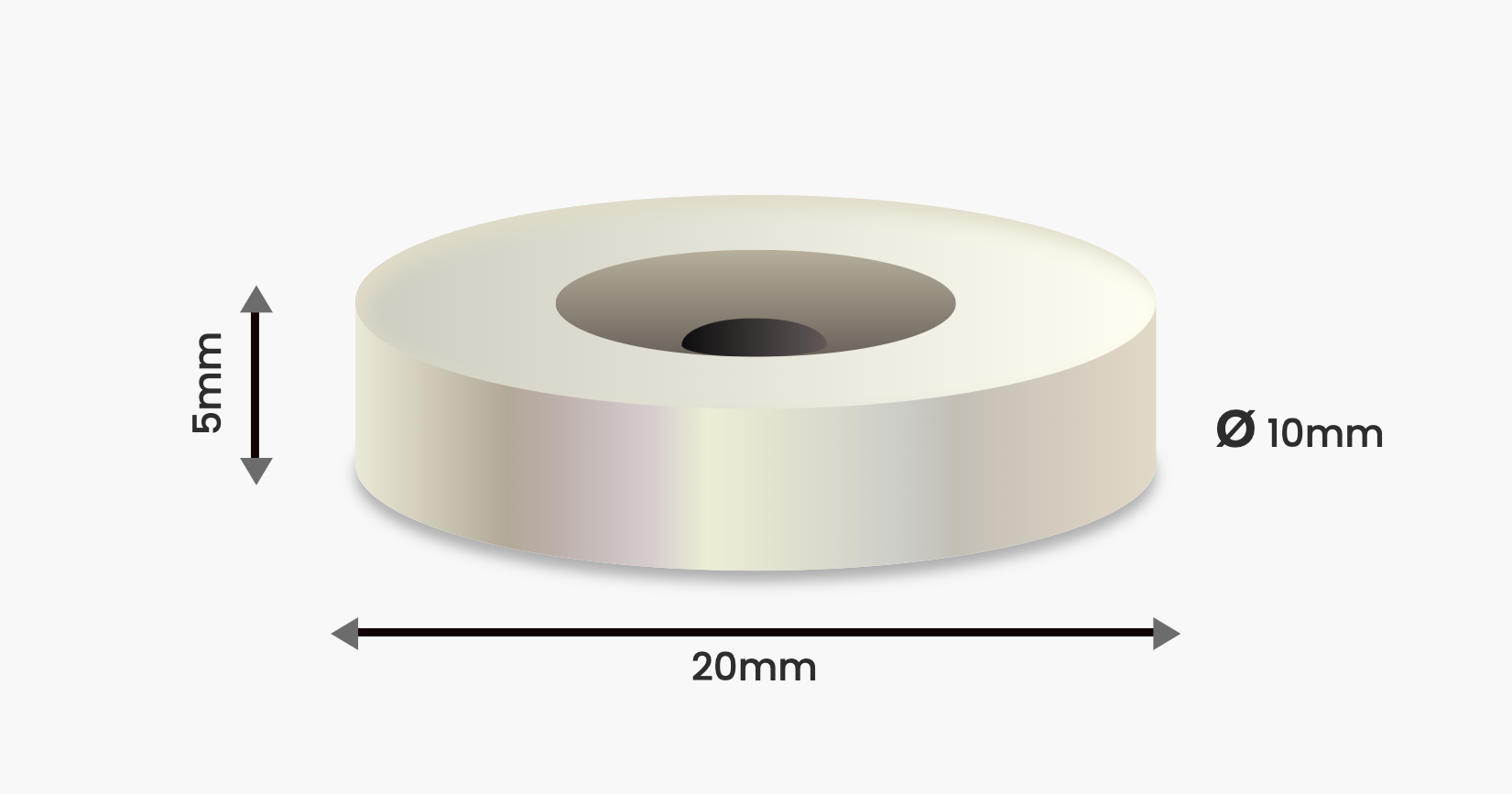

Design your own Ring, Cyl or Block -magnet with our magnet calculator. See which magnets we have have on stock based on your entered values. If we don’t have any article on stock with either your requested size or any that meets your requirement, simply make a quote request and we get back to you with price.

Published: 2025-05-21

![]() Daniel Gårdefelt

Daniel Gårdefelt

Magnets in Restaurant Kitchens

In the food and processing industries, magnetic filter bars and separators are used to ensure that unwanted metallic particles do not end up in o...

Show more >

Published: 2025-05-16

![]() Daniel Gårdefelt

Daniel Gårdefelt

Global supply challenges and HYAB’s role

Although the situation is beginning to look more promising, with reduced tariffs between the USA and China, the underlying issues of the ongoing ...

Show more >