Blog page

Recent Post

Magnets in Restaurant Kitchens

Global supply challenges and HYAB’s role

Electromagnets – a more controllable magnet

Magnetic filtration in the process industry

Sheet metal handling – Easier with magnets

Published: 2025-01-27

![]() Daniel Gårdefelt

Daniel Gårdefelt

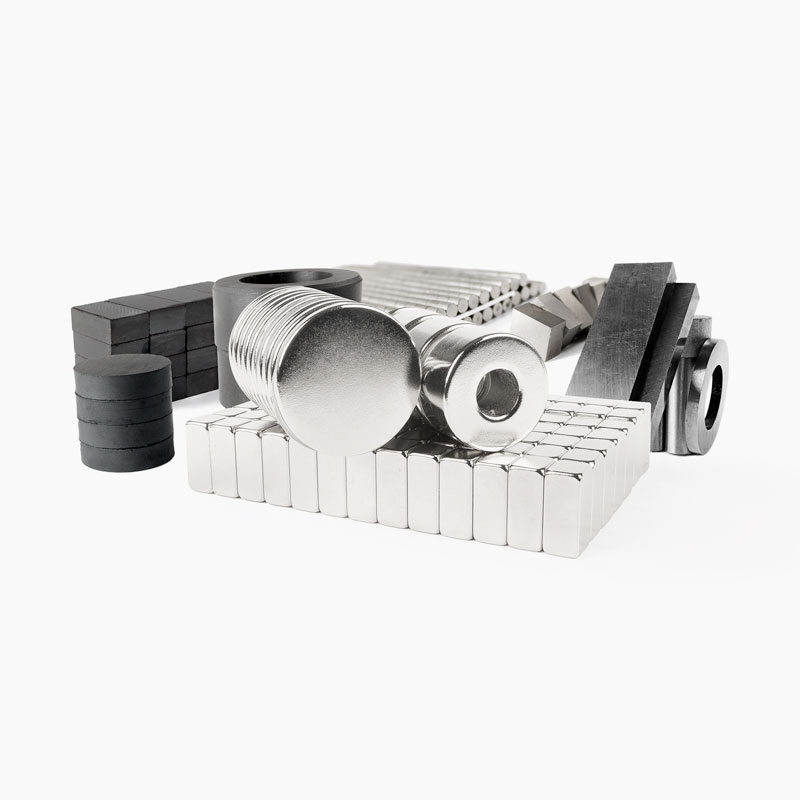

Magnet manufacturing process: From raw material to finished magnet

In today's technology, magnets are in everything from refrigerator magnets/advertising magnets to speakers and sophisticated medical devices...

Show more >

Published: 2024-04-24

![]() Daniel Gårdefelt

Daniel Gårdefelt

How changes in the global supply chain affect the price and production of magnets

Magnets are important parts of many businesses, such as electronics, cars, and renewable energy. The global supply chain has a big impact on how ...

Show more >

Published: 2023-04-28

![]() Daniel Gårdefelt

Daniel Gårdefelt

Fishing with magnets

There's a lot you can find at the bottom of a lake. At the end of last year, the Uppsala Magnetfishing Association exhibited a large amount ...

Show more >

Published: 2023-04-17

![]() Daniel Gårdefelt

Daniel Gårdefelt

FAQ - Frequently Asked Questions

FAQ - which questions about magnets do we most often get from our customers? 1. Are neodymium and rare earth magnets the same thing? Neodym...

Show more >

Published: 2023-04-05

![]() Daniel Gårdefelt

Daniel Gårdefelt

How does a neodymium magnet take its shape

The process of forming a neodymium magnet begins with the raw materials. Neodymium, iron and boron are melted together in a furnace and then cool...

Show more >

Published: 2023-04-05

![]() Daniel Gårdefelt

Daniel Gårdefelt

Neodymium magnets - a few health and safety precautions

Neodymium magnets have become more popular than ever because of the material's strong properties, and are now found in everyday applications...

Show more >

Published: 2023-03-15

![]() Daniel Gårdefelt

Daniel Gårdefelt

Magnetic materials for nuclear applications

Magnets are important in many fields, including the nuclear industry. Magnetic materials serve many functions in nuclear power applications, incl...

Show more >

Published: 2023-03-10

![]() Daniel Gårdefelt

Daniel Gårdefelt

Magnets in wind turbines and other renewable energy systems

Wind power is becoming increasingly popular as countries and companies try to reduce their carbon footprint and transition to more sustainable en...

Show more >

Published: 2023-03-01

![]() Daniel Gårdefelt

Daniel Gårdefelt

Magnets in audio speakers and headphones

Magnets are an important component in many modern audio systems, as they play an important part in the generation of sound waves. In this article...

Show more >

Published: 2023-02-28

![]() Daniel Gårdefelt

Daniel Gårdefelt

A closer look on magnets in the automotive industry

Magnets are a key component of many modern automobiles, with applications ranging from power generation and fuel efficiency to safety systems and...

Show more >

Published: 2023-02-27

![]() Daniel Gårdefelt

Daniel Gårdefelt

Factors Affecting Performance and Lifetime of Magnets

Electric motors, medical equipment and many other industries depend on magnets. The cost-effectiveness of the product in which a magnet is used i...

Show more >