Blog page

Recent Post

Magnets in Restaurant Kitchens

Global supply challenges and HYAB’s role

Electromagnets – a more controllable magnet

Magnetic filtration in the process industry

Sheet metal handling – Easier with magnets

Published: 2023-06-19

![]() Daniel Gårdefelt

Daniel Gårdefelt

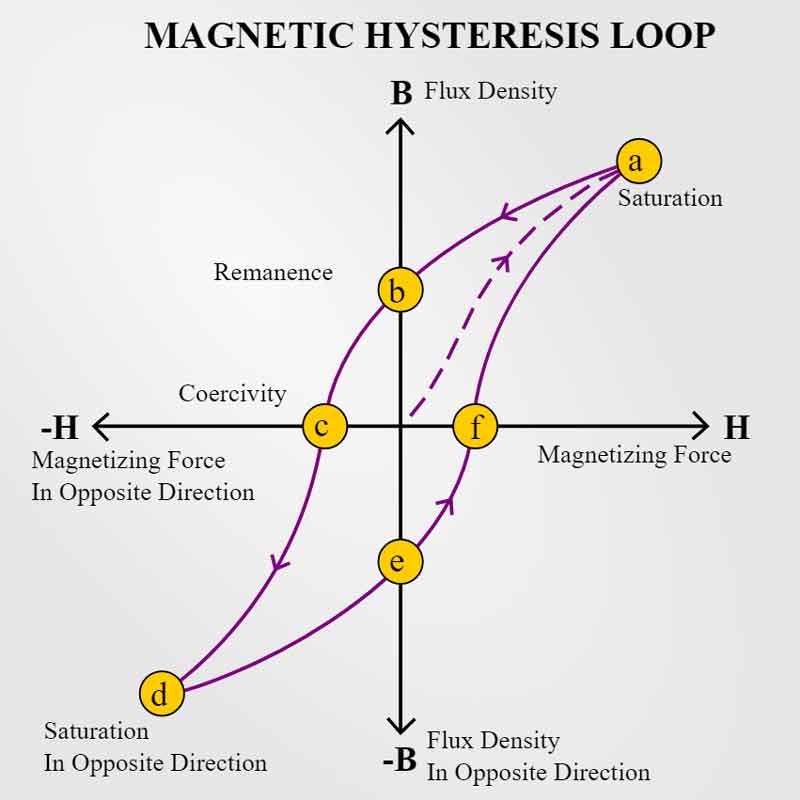

Magnetic saturation: Optimizing magnetic material

Magnetic saturation is an important factor affecting the effectiveness of magnets in a variety of applications, including electric motors and mag...

Show more >

Published: 2023-05-05

![]() Daniel Gårdefelt

Daniel Gårdefelt

Some reasons why it is important to measure and calibrate magnetic fields

Measurement and calibration of magnetic fields are important parts of many industries, such as manufacturing, aerospace and medicine. These steps...

Show more >

Published: 2023-04-17

![]() Daniel Gårdefelt

Daniel Gårdefelt

Samarium Cobalt magnets: What is it and how is it made

Samarium Cobalt (SmCo) magnets are a form of rare earth magnets characterized by their exceptional magnetic properties and high demagnetization r...

Show more >

Published: 2023-04-13

![]() Daniel Gårdefelt

Daniel Gårdefelt

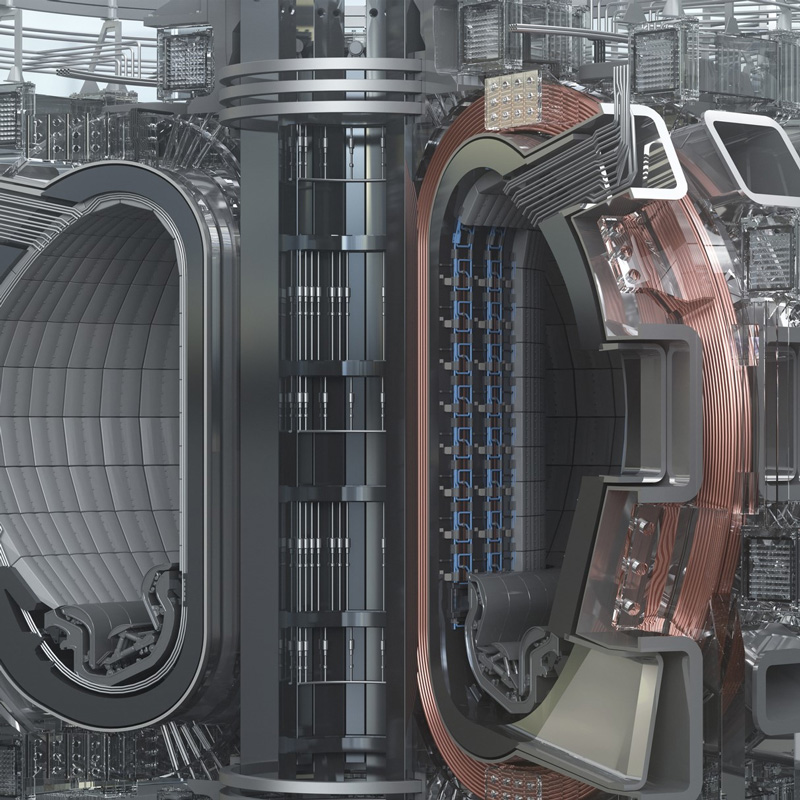

A giant leap for nuclear fusion: the breakthrough in magnetic technology

Nuclear fusion, the process of combining atomic nuclei to release energy, has been considered the holy grail of clean and sustainable energy for ...

Show more >

Published: 2023-04-11

![]() Daniel Gårdefelt

Daniel Gårdefelt

What are the rules and certifications for magnets

Learn the basic regulations and certifications for magnets to ensure safety, quality and compliance in a variety of industries and applications. ...

Show more >

Published: 2023-03-16

![]() Daniel Gårdefelt

Daniel Gårdefelt

Magnets in elevators

Elevators have become a part of our daily life, making it easy for us to move between floors and buildings. Magnetic materials are essential to t...

Show more >

Published: 2023-03-09

![]() Daniel Gårdefelt

Daniel Gårdefelt

Magnets play a major role in declining counterfeiting and fraud

Magnetic ink is a type of ink that contains tiny magnetic particles, allowing it to be read by magnetic field-detecting machines. This ink is com...

Show more >

Published: 2023-01-10

![]() Daniel Gårdefelt

Daniel Gårdefelt

Neodymium price

Neodymium magnets are an incredibly powerful type of permanent magnet made from an alloy of neodymium, iron and boron. They’re used in a va...

Show more >