Recent Post

Magnets in Restaurant Kitchens

Global supply challenges and HYAB’s role

Electromagnets – a more controllable magnet

Magnetic filtration in the process industry

Sheet metal handling – Easier with magnets

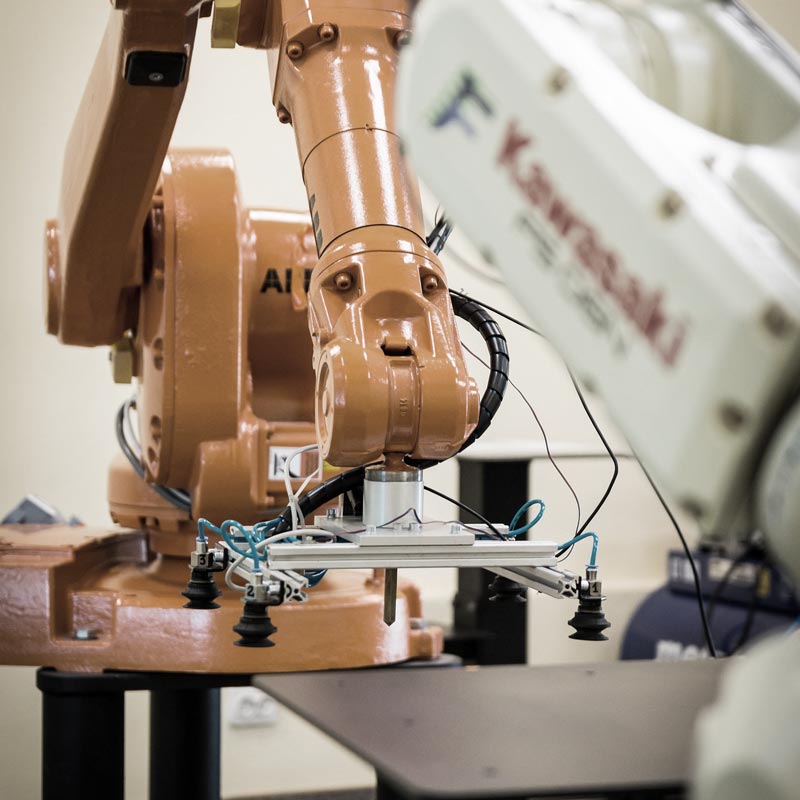

Magnets in industrial automation and robotics

Published: 2023-03-13 11:25:55 • Daniel Gårdefelt

Magnets are utilized extensively in industrial automation and robotics due to their numerous advantages over other material manipulation techniques. Magnets are highly effective at holding and moving objects, making them an excellent choice for industries whose processes require precision and efficiency. Magnets are now an indispensable tool for automating and streamlining a variety of processes in industries ranging from manufacturing to healthcare.

In industrial automation, magnets are utilized for a variety of purposes. Magnets are one of the most prevalent applications in conveyors, where they are utilized to move parts and products along the line. This helps to improve efficiency and reduce the risk of product damage. Magnets are also utilized in pick-and-place systems, where they are utilized to move and place objects in various locations. This is especially useful in packaging and other industries where objects must be moved quickly and precisely.

Magnets have numerous applications in robotics, including material handling, assembly, and inspection. Commonly used in material handling applications, magnetic grippers can pick up and transport objects without causing damage. Magnetic grippers are particularly useful in industries where fragile objects, such as glass or ceramics, are handled. In assembly applications, they can be used to hold parts in place while they are being assembled.

Magnets are utilized in inspection applications to hold parts in place while they are being inspected. This is especially useful in industries like aerospace and automotive where parts must be inspected for quality and precision. Magnets are also utilized in welding applications to hold parts in place while they are welded.

Magnets do not require physical contact with the object being moved, unlike other methods such as suction cups or clamps. This means that they can hold objects of various sizes and shapes, making them more versatile than alternative methods. Magnets require less maintenance than other methods because there are no moving parts to wear out or require lubrication.

Magnets' ability to function in harsh environments is another benefit of their use. Magnets can function in high-temperature environments, making them ideal for use in metalworking and foundries. They can also operate in environments containing hazardous chemicals or other substances, making them suitable for use in the pharmaceutical and chemical sectors.

Magnets have become an indispensable component of industrial automation and robotics. They offer numerous advantages over other methods of manipulating materials, such as their ability to hold objects securely in place, their versatility, and their ability to function in harsh environments. As industries continue to evolve and demand more efficient and effective production methods, the use of magnets in industrial automation and robotics is likely to increase.