Recent Post

Magnets in Restaurant Kitchens

Global supply challenges and HYAB’s role

Electromagnets – a more controllable magnet

Magnetic filtration in the process industry

Sheet metal handling – Easier with magnets

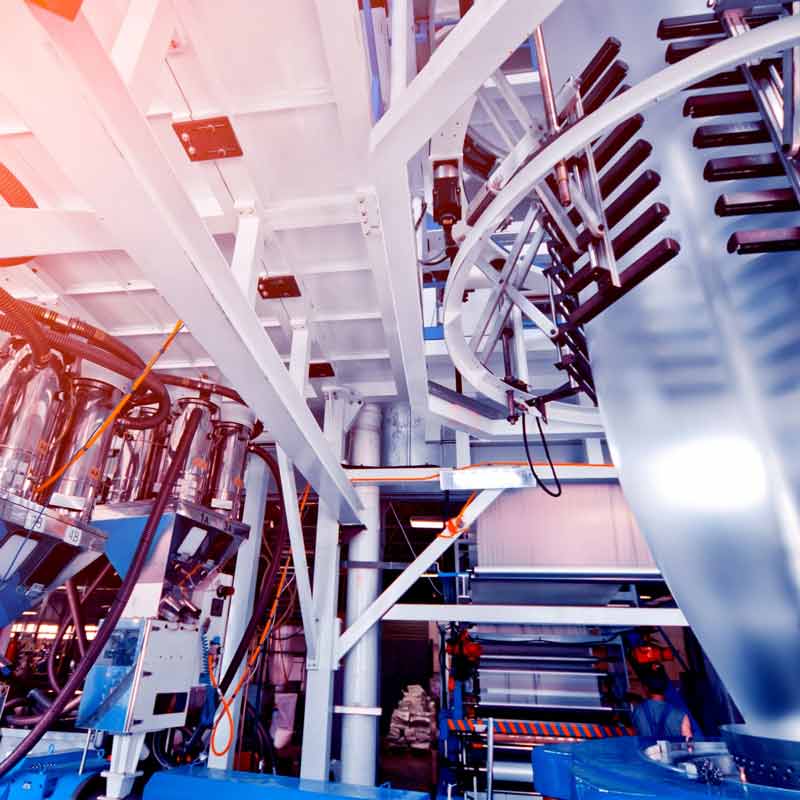

How magnets are used in the manufacture of plastics

Published: 2023-03-30 09:02:37 • Daniel Gårdefelt

Magnets are important for the production of plastics. Without magnets, it would be difficult, if not impossible, to manufacture certain types of plastic objects.

In the manufacture of plastics, one of the primary applications for magnets is the separation of ferrous and non-ferrous materials. Magnets can be used to separate non-ferrous from ferrous materials, which is important given that ferrous materials can contaminate plastics during manufacturing. This may result in a product of lower strength or quality.

Another way magnets are used in the plastic manufacturing process is to create magnetic materials. In the manufacture of plastic resin, magnetic particles can be added to make plastics with magnetic fields, we call these plastic bound - see all our plastic bound articles here. These magnetic materials have a wide range of applications, including the manufacture of magnetic credit card strips and magnetic automotive components.

Magnets are also used to help create plastic items to spec. For example, during the manufacturing process of medical plastic products magnets can be used to hold the device in place. This ensures that the part is manufactured with precision and consistency.

Magnets are also used in the recycling of plastic products. Magnets can be used to separate ferrous and non-ferrous components from plastic waste, a crucial step in the recycling process. This enables more efficient recycling and can reduce the amount of waste sent to landfills.

Magnets play an important role in the plastic manufacturing process. They are used to separate materials, produce magnetic materials, ensure precision and accuracy, and facilitate the recycling process.