Recent Post

Magnet manufacturing process: From raw material to finished magnet

How changes in the global supply chain affect the price and production of magnets

Brain teasers and Magnetic Puzzles: An Enjoyable Method of Learning

Merry Christmas and a Happy New Year!

The role of magnets in high-speed electric paragliding technologies

The impact of magnets on advanced materials for additive manufacturing and 3D printing

Published: 2023-05-08 14:29:11 • Daniel Gårdefelt

Today we'll find out how magnets are used to make advanced materials for 3D printing and additive manufacturing, opening up new possibilities for design and production.

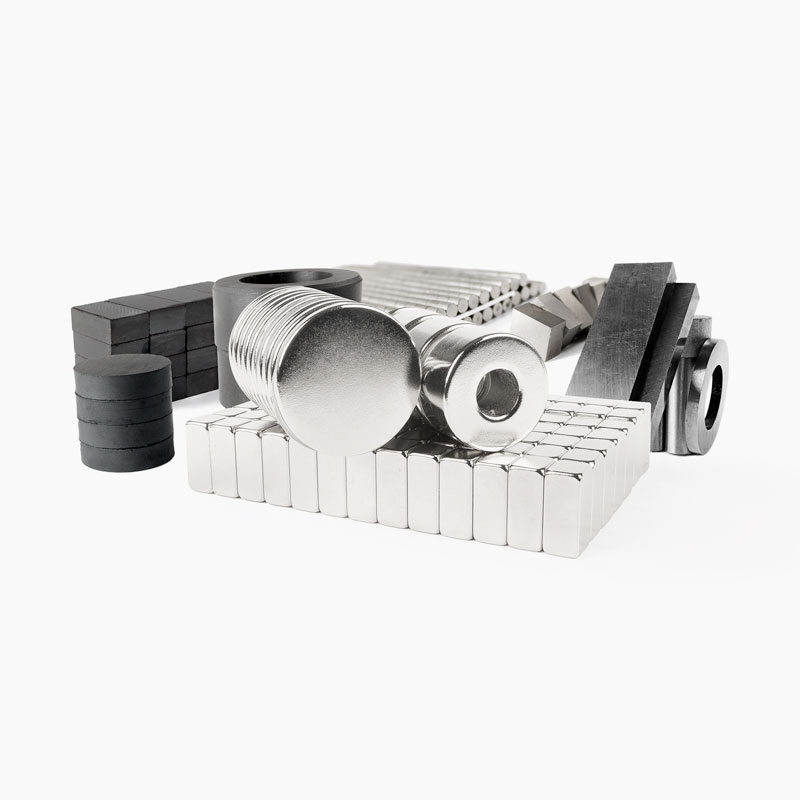

The way we humans design and manufacture a wide range of products has changed in recent years due to additive manufacturing and 3D printing. Magnets are an important part of the fabrication of these advanced materials, and they have their own unique properties and advantages.

Magnetic materials for 3D printing

The use of magnetic materials for 3D printing is one of the most exciting innovations in additive manufacturing.

1. Magnetic Filaments: These filaments mix traditional thermoplastics with magnetic particles, such as iron, to make a 3D printing material that can be magnetized. Magnetic filament makes it possible to manufacture magnets in any shape and complicated magnetic parts that can be used in many different ways.

2. Soft Magnetic Composites: For applications that need soft magnetic materials, you can 3D print advanced composites made from a polymer binder and soft magnetic particles. This gives you more freedom in design and prototyping.

Magnets are used in powder bed fusion.

Magnets are also used in processes such as selective laser sintering (SLS) and selective laser melting (SLM) that use powder bed fusion:

1. Powder handling: Magnets can be used to control and move metal powder during the manufacturing process. This ensures that material is layered accurately and evenly.

2. Better efficiency: By using magnets to control the powder bed, manufacturers can improve the overall efficiency and accuracy of the additive manufacturing process. This reduces material waste and production time.

How magnetic materials for 3D printing will change in the future

As the additive manufacturing industry continues to grow, magnets are likely to play a larger role in the manufacturing of high-tech materials. An example is Multi-Material 3D Printing. In the future, it may be possible to print both magnetic and non-magnetic materials at the same time, which would make it possible to make complex, multi-functional parts.

New magnetic alloys: Research into new magnetic alloys and materials can lead to the creation of additive manufacturing magnetic materials that are even more useful and flexible.