Recent Post

Magnet manufacturing process: From raw material to finished magnet

How changes in the global supply chain affect the price and production of magnets

Brain teasers and Magnetic Puzzles: An Enjoyable Method of Learning

Merry Christmas and a Happy New Year!

The role of magnets in high-speed electric paragliding technologies

Magnetic filter bars - functionality and applications

Published: 2023-04-26 10:57:18 • Daniel Gårdefelt

Magnetic filter bars is an effective way to separate and remove ferrous impurities from many different types of material. These rods, which are made of permanent magnets encased in a stainless steel tube, are a simple and effective way to capture and separate particles, ensuring the purity and quality of products in many different industries. In this article we look at how separator bars work and what they can be used for.

How do magnetic separator bars work?

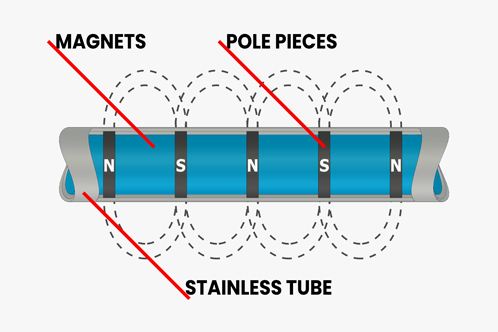

The purpose of these rods is to pick up, hold and separate iron particles. For the most part, they have several strong permanent magnets, such as neodymium, inside a strong stainless steel tube. The tube preserves the magnets and makes them have a long life and gives them a clean, easy-to-clean surface.

The magnets in the tube are positioned so that south-pole is towards south-pole and north towards north. When you force cuffs in this way, you extend (push out) the magnetic field, which is very important for the rod to pick up iron debris and particles from as far away as possible.

In many situations, more than one separator rod is placed in a grid or casing to make a system with a larger contact area and better separation.

magnetic filter bars can be manufactured in different lengths, diameters, magnetic strengths and with different types of mounting options (such as threading at the end) to meet different needs. The choice of magnetic material, such as neodymium or ferrite magnets, depends on things like how strong a magnet you want it to be, how much heat it will be exposed to, and cost.

How magnetic filter bars are used

Separator bars are used in many different areas and situations, such as:

In the food and beverage industry, it is very important to ensure that the food is clean and safe. Magnetic separator bars can be used to remove ferrous impurities from raw materials such as grains, spices and liquids. This prevents product recalls and protects consumer health.

Pharmaceutical industry: In the pharmaceutical industry, it is important to keep the quality of the products high and meet strict regulatory standards. magnetic filter bars can help remove iron-containing impurities from powders, granules and liquid suspensions, and ensure the purity of medicines and dietary supplements.

Chemical industry and plastics industry: In the chemical and plastics industry, separator rods can be used to remove iron particles from raw materials and finished products. This improves the quality of the products and prevents damage to the processing equipment.

Recycling and Waste Management: magnetic filter bars can help separate ferrous material from non-ferrous material during recycling and waste management processes. This makes recycling more efficient and reduces the amount of rubbish that ends up in landfill.

Mining and Mineral Processing: magnetic filter bars can be used in the mining and mineral processing industry to separate valuable minerals from gangue material. This makes mining more efficient and profitable.

We can therefore conclude that magnetic filter bars are a reliable and effective way to separate and get rid of ferrous impurities. These separator rods have a simple yet effective design that helps improve product quality, protect equipment and meet regulatory standards.